Difference between revisions of "Prusai3"

| Line 18: | Line 18: | ||

* Extruder nozzle size: 0.35mm | * Extruder nozzle size: 0.35mm | ||

* It can print overhangs of <45degrees without scaffolding. | * It can print overhangs of <45degrees without scaffolding. | ||

| − | |||

=== Printing supplies === | === Printing supplies === | ||

| Line 28: | Line 27: | ||

==== PLA ==== | ==== PLA ==== | ||

| − | Bed temperature: 60 | + | * Bed temperature: 60 |

| − | Extruder temperature: 185 | + | * Extruder temperature: 185 |

==== ABS ==== | ==== ABS ==== | ||

| − | Bed temperature: 110 (but it seems the bed doesn't seem to reach that at the moment) | + | * Bed temperature: 110 (but it seems the bed doesn't seem to reach that at the moment) |

| − | Extrude temperature: 215 | + | * Extrude temperature: 215 |

=== Toolchain === | === Toolchain === | ||

# Make or download 3d objects in STL format. | # Make or download 3d objects in STL format. | ||

| − | # The slicer software ([http://slic3r.org Slic3r]) will generate the actual printer commands (G-code). This .gcode file is loaded into the next stage. | + | # The slicer software ([http://slic3r.org Slic3r]) will generate the actual printer commands (G-code). This .gcode file is loaded into the next stage. Sometimes the slicer complains (even if blender finds no problems with the model). To fix it use the following magic webservice: curl --data-binary @orig.stl stlfix.jit.su -o fixed.stl (this is an interface to cloud.netfabb.com ) |

| + | # Load the .gcode file into the printer software and print. | ||

Revision as of 18:33, 30 April 2013

| TechInc Inventory | |

|---|---|

| |

| Description | 3d Printer |

| Make | RepRap |

| Model | i3 |

| Manufacturer Link | http://reprap.org/wiki/Prusa i3 |

| Category | Other |

| Operational Status | Working |

| Super Users | User:amx109, User:Nathan7 |

| Received at | |

| Acquisition Details | We Built It |

| Owner | TechInc |

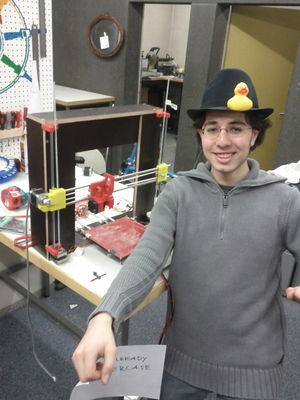

Our 3d printer based on the Prusa i3 design.

Specifications

- Maximum print sizes: 170mm, 170mm, "a lot" (x,y,z). However the printing will suffer from "warping" much before those limits are reached.

- Minimal print resolution: ?, ?, ? (x, y z).

- Extruder nozzle size: 0.35mm

- It can print overhangs of <45degrees without scaffolding.

Printing supplies

- 3mm PLA (hard and britle, doesn't warp much, biodigradable)

- 3mm ABS (soft and tough - LEGO like plastic, warps much more the PLA)

Printer settings

Settings for the printer depend on the kind of filament.

PLA

- Bed temperature: 60

- Extruder temperature: 185

ABS

- Bed temperature: 110 (but it seems the bed doesn't seem to reach that at the moment)

- Extrude temperature: 215

Toolchain

- Make or download 3d objects in STL format.

- The slicer software (Slic3r) will generate the actual printer commands (G-code). This .gcode file is loaded into the next stage. Sometimes the slicer complains (even if blender finds no problems with the model). To fix it use the following magic webservice: curl --data-binary @orig.stl stlfix.jit.su -o fixed.stl (this is an interface to cloud.netfabb.com )

- Load the .gcode file into the printer software and print.