BZT PF-1000P: Difference between revisions

m link |

No edit summary |

||

| (One intermediate revision by the same user not shown) | |||

| Line 15: | Line 15: | ||

On 16 March 2022 we have picked up a CNC mill and placed it in the dirty room. | On 16 March 2022 we have picked up a CNC mill and placed it in the dirty room. | ||

It has been given to us on loan by Vasili, another tenant from the building. | It has been given to us on loan by Vasili, another tenant from the building. TODO: figure out who Vasili is. | ||

This machine uses Mach4 to control it. | |||

= Specifications = | = Specifications = | ||

| Line 32: | Line 28: | ||

= Usage = | = Usage = | ||

'''We will require''' that any person working with this machine has received specific training for this machine. Contact the CNC channel on slack. | |||

If you have recieved training, here is a brief reminder of how to use the machine: | |||

Generate your gcode with a suitable bit of CAM software. Fusion 360 is installed on the CAD computer. | |||

copy your file to the CNC computer. | |||

insert your bit and tighten it well. make sure you use the correct collet. | |||

Make sure the cooling is on and running. | |||

clamp your work piece down. Use a surface under your piece if you plan to cut through. | |||

load your file (file operations, in the right) | |||

Zero X and Y. | |||

reduce your jog speed to ~4% | |||

use the 'spindle CW' button to activate the spindle. | |||

Zero your Z with the spindle running, than raise it and disengage the spindle. | |||

regenerate toolpath | |||

check that your X and Y are within bounds with movement. make sure there are no potential colissions. | |||

if there is doubt, also check Z. | |||

set youe spindle speed | |||

activate the spindle with 'spindle CW' | |||

run 'cycle gcode start' | |||

use a vacuum cleaner as it runs. | |||

If anything goes wrong write in the CNC telegram channel. | |||

= Tool guardians = | = Tool guardians = | ||

Latest revision as of 22:24, 17 December 2024

| TechInc Inventory | |

|---|---|

| |

| Description | 3 axis portal style CNC mill. Processable area ca. 660x800mm |

| Make | BZT |

| Model | PF-1000P |

| Manufacturer Link | https://www.bzt-cnc.de/produkte/baureihe-pf |

| Category | Mechanics |

| Operational Status | Functional |

| Super Users | Piele, User:Justa |

| Received at | 2022/03/16 |

| Acquisition Details | The machine is on loan from Vasili. |

| Owner | Vasili |

Introduction

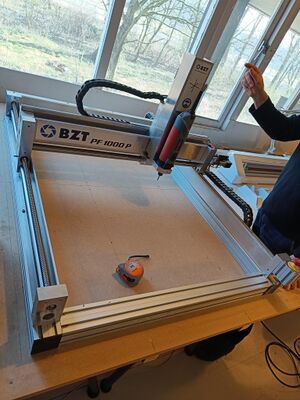

On 16 March 2022 we have picked up a CNC mill and placed it in the dirty room.

It has been given to us on loan by Vasili, another tenant from the building. TODO: figure out who Vasili is.

This machine uses Mach4 to control it.

Specifications

The Machine is built by the German machine factory BZT, who build a variety of CNC milling machines.

The dimensions of the machine itself are 1300 x 1030 x 610 mm, but it is placed in an enclosure which is 1420 x 1100 x 700mm.

[TODO: add more specifications]

Usage

We will require that any person working with this machine has received specific training for this machine. Contact the CNC channel on slack.

If you have recieved training, here is a brief reminder of how to use the machine:

Generate your gcode with a suitable bit of CAM software. Fusion 360 is installed on the CAD computer.

copy your file to the CNC computer.

insert your bit and tighten it well. make sure you use the correct collet.

Make sure the cooling is on and running.

clamp your work piece down. Use a surface under your piece if you plan to cut through.

load your file (file operations, in the right)

Zero X and Y.

reduce your jog speed to ~4%

use the 'spindle CW' button to activate the spindle.

Zero your Z with the spindle running, than raise it and disengage the spindle.

regenerate toolpath

check that your X and Y are within bounds with movement. make sure there are no potential colissions.

if there is doubt, also check Z.

set youe spindle speed

activate the spindle with 'spindle CW'

run 'cycle gcode start'

use a vacuum cleaner as it runs.

If anything goes wrong write in the CNC telegram channel.

Tool guardians

Currently the tool guardians are: Piele and Justa

Since this project has just started and is in progress, anyone who is interested in becoming a tool guardian for this machine is invited to let us know.